I-carbon fiberItekhnoloji eyomeleziweyo yokulungiswa kokuqhekeka kwebhulorho yohola wendlela iye yathandwa ngokubanzi kwiminyaka yakutshanje ngenxa yeenzuzo zayo kulwakhiwo olulula kunye neshedyuli eqinileyo. Uninzi lweebhuloho zohola wendlela zineentanda ezibonakalayo okanye ezingabonakaliyo kwimiqadi yesiseko ngenxa yexesha elide lenkonzo okanye umsebenzi wokugcwala ixesha elide. Ukuqhekeka ngokubanzi, uninzi lokusetyenziswa kwe-carbon fibre material reinforcement ingaba. Eli khaya lilandelayo lokuqinisa liya kwazisa ulwakhiwo lokuqiniswa kwelaphu le-carbon fiber kwiintanda zebhulorho.

Itekhnoloji yolwakhiwo lwelaphu lekhabhoni yokuqinisa ilaphu lokuqhekeka kwebhulorho inezi nkqubo zintathu zilandelayo:

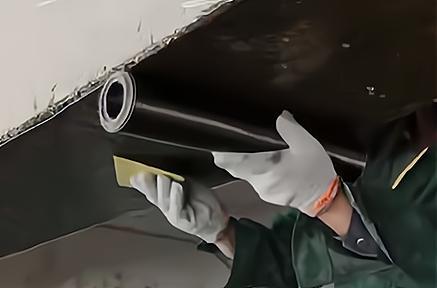

Inyathelo lokuqala kukusombulula umaleko ongezantsi webhulorho yendlela enkulu

1. Lungisa iintanda kulwakhiwo lweglu kwibhulorho yesiseko semiqadi eneentanda.

2. Ukuphelisa izikhundla ezithotyiweyo zomgangatho wekhonkrithi, njengokuphalaza, ukukhulula, ukumila kwenqatha lobusi kunye nokhukuliseko, kwaye uqhube ukucoca, ukugawula kunye nokupolisha. Emva kokuba ubuso bomile kwaye bucaphukile, lungisa i-convex kunye nezikhundla ze-concave ze-concrete surface kunye nezinto zokulungisa izinto eziluhlaza. Ukuba kukho imiphetho erhabaxa, sebenzisa i-sandpaper ukubhuqa kunye nokupolisha. Fumana isicwangciso sokuchukumisa isandla siziva somelele, sinokuqhuba inkqubo elandelayo yokwakha ubunjineli.

3. I-Yin kunye ne-Yang Angle ye-carbon fiber cloth paste kufuneka iphuculwe ibe yi-arc shape, kwaye umgca we-Angle ye-Yin kufuneka wenziwe kwi-arc fillet ukulungisa izinto eziluhlaza, kwaye i-arc half meridian ayifanele ibe ngaphantsi kwe-arc. 25mm.

Isinyathelo sesibini, gcoba isiseko seglue

I-1, ukuthunyelwa kwe-substrate efanelekileyo kufuneka isetyenziswe ngokukhawuleza, kunye nebrashi ethambileyo elahlayo okanye i-roller eyenziwe ngokukodwa iya kusula ngokulinganayo i-substrate ebusweni bekhonkrithi, musa ukuvuza ibrashi, ukuhamba okanye i-bubble. Khangela indawo yeglue emva kokuba isiseko seglue somile kwaye siqinile. Ukuba umphezulu weglu unemiphetho erhabaxa, sebenzisa i-sandpaper yokusila ukupolisha kunye nokupolisha kakuhle. Ukuba iglue yonakalisiwe, kufuneka ihlanjululwe kwakhona kwaye inkqubo elandelayo inokuqhutywa emva komile kwaye iqinile.

2. Inkqubo elandelayo yezobuchwepheshe kufuneka iqhutywe ngokukhawuleza emva kokuba isiseko seglue esomile kwaye siqinile. Ukuba ixesha lokuxubha lidlula i-7d, i-glue yesiseko sokuqala kufuneka isuswe ngokucacileyo ngomatshini wokupolisha kwaye yosule kwakhona.

Inyathelo lesithathu, umqadi wesiseko sebhulorho yehola wendlela encanyathiselwe iteknoloji yokuqinisa ilaphu lolwakhiwo lwelaphu kunye neengxaki eziqhelekileyo

1. Ayifanelekanga ukwakhiwa kobunjineli ngeentsuku zemvula okanye phantsi kwemigangatho yegesi emanzi kunye nebandayo. Ukuba kuyimfuneko ukusebenza kumalungu asele emanzi kwaye abandayo, qiniseka ukuba umoya womise umphezulu wamalungu afakwe ngaphambili okanye usebenzise i-adhesives professional.

I-2, i-carbon fiber ilaphu intlama kufuneka iqhutywe phantsi komgangatho wokushisa osebenzayo we-5 ~ 35 ℃, ukusetyenziswa kwe-adhesive kufuneka kuhlangabezane neemfuno zokusetyenziswa kobushushu bokusebenza.

3. Kumgangatho wekhonkrithi oza kuqiniswa, ulwakhiwo kunye nokunyuswa kuya kwenziwa ngokomzobo woyilo, kwaye indawo yomaleko ngamnye we-chemical fiber polymer material iya kuchazwa.

4. Sika i-carbon fiber cloth ngokwemigaqo yeskimu soyilo. Ubude be-lap ye-carbon fiber polymer reinforcement ayifanelekanga ngaphantsi kwe-100 mm, kwaye indawo ye-lap yokuqiniswa kwensimbi kufuneka igweme indawo engundoqo yokuthwala. Ilaphu elisikiweyo kufuneka lifakwe ngokufanelekileyo kwidiski kwaye linenombolo. Sele zisikiwe izixhobo zepolymer zemichiza kufuneka zifakwe ngokukhawuleza.

5. Ngaphambi kokuncamathisela ilaphu le-carbon fiber, sula indawo yekhonkrithi kwakhona ukuze uqinisekise ukuba indawo yokuncamathela ivelisa uthuli. Xa uxubha i-adhesive ebusweni bekhonkrithi, isisombululo se-colloidal akufanele sihambe; Isisombululo se-Colloid sigxothe ukuba singalawuli umgca; Brasha ngokulinganayo.

6, Ncamathisela ngaphakathi kwi-chemical fiber polymer material, kufuneka iqhutywe ngokuhambelana nomyalelo wokunyuka. Ilaphu le-carbon fiber likhutshiwe ukusuka kwelinye icala ukuya kwelinye kunye ne-roller barrel ukususa i-bubble phakathi kwesisombululo se-colloidal kunye ne-chemical fiber polymer material, ukwenzela ukuba isisombululo se-colloidal singene kwi-chemical fiber polymer material, emanzi kwaye egudileyo. Umgqomo osetyenzisiweyo akufanele ubangele umphumo we-electrostatic kuyo yonke inkqubo yokwenziwa kwe-extrusion.

I-7, ekhethwe ngemicu emininzi okanye umaleko ophindwe kabini wefayibha yepolymer yokuqinisa imathiriyeli, kwindawo yangaphambili yelaphu lefayibha umphezulu weminwe yokuchukumisa iminwe yomile, intlama encamathelayo ngoko nangoko emva komaleko wemathiriyeli yefayibha yepolymer.

I-8, umaleko wokugqibela wemichiza yefayibha yepolymer ulwakhiwo lobunjineli lugqityiwe, kumphezulu we-symmetrical sula umaleko we-epoxy resin yokungena (ukhuseleko lomphezulu jikelele wokhuseleko

https://www.heatresistcloth.com/carbon-fiber-fabric/

Ixesha lokuposa: Apr-18-2023